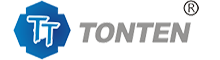

Máquina Trituradora de Eixo Duplo para Sacos Tecidos e Tecidos Velhos

Detalhes do produto:

| Lugar de origem: | CHINA |

| Marca: | TONTEN |

| Número do modelo: | TT-S1000 |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1 conjunto |

|---|---|

| Preço: | Negociável |

| Detalhes da embalagem: | Modelos pequenos são embalados em caixas de madeira, modelos grandes carregam em contentores |

| Tempo de entrega: | 7-10 dias de trabalho |

| Termos de pagamento: | T/T. |

| Habilidade da fonte: | 20 conjuntos por mês |

|

Informação detalhada |

|||

| Energia motora: | 30kW | Número de lâminas do triturador: | 20 peças |

|---|---|---|---|

| Tamanho portuário da alimentação: | 1000x800 mm | Material corporal: | Aço carbono |

| Modo de unidade: | Acionamento de motor duplo | Materiais aplicáveis: | Madeira de pano velha de bolsa tecida |

| Dimensões: | 3000 x 2000 x 2000 mm | Nome do modelo: | Triturador de triturador de eixo duplo |

| Destacar: | máquina de trituração de sacos tecidos,triturador de tecido de eixo duplo,máquina trituradora de madeira |

||

Descrição de produto

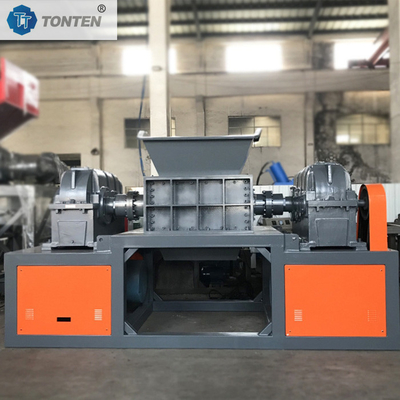

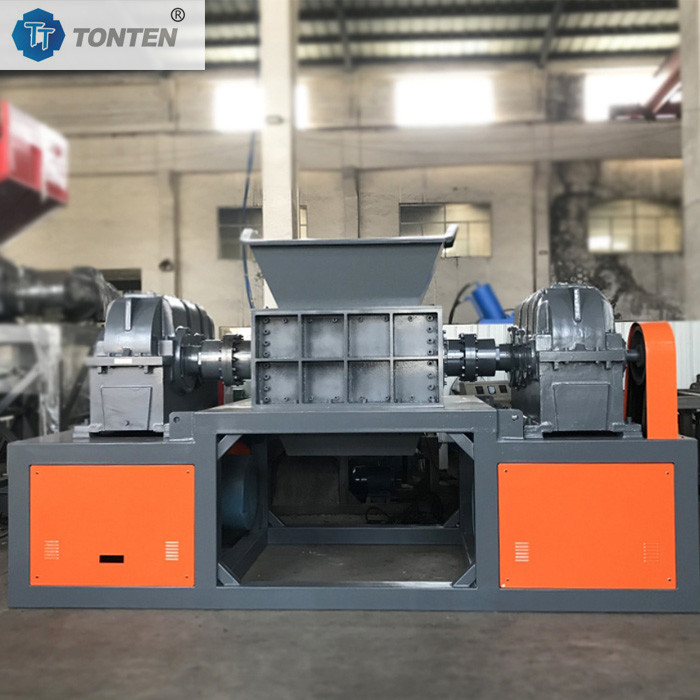

Saco de tecido triturador de eixo duplo triturador de tecido velho máquina de madeira

Características estruturais:

Design de eixo duplo: Utilizando dois eixos rotativos paralelos, um triturador de eixo duplo fornece trituração mais uniforme, reduzindo o entupimento e a estagnação do material.

Sistema de lâminas: Equipado com várias lâminas de triturador, normalmente feitas de aço de alta liga para alta resistência e resistência ao desgaste.A disposição racional das lâminas garante a trituração eficaz de uma grande variedade de materiais.

Estrutura do corpo: O corpo é tipicamente construído de aço carbono pesado, garantindo estabilidade e durabilidade sob altas cargas.

Sistema de potência: os trituradores de eixo duplo estão equipados com dois motores, fornecendo potência poderosa e garantindo um triturador eficiente e rápido.

Entrada de alimentação: a entrada de alimentação larga, normalmente de 1000 x 800 mm, facilita a entrada de material e acomoda uma grande variedade de materiais.

Sistema de controlo: os trituradores de dois eixos estão equipados com um sistema de controlo automático PLC, que permite a operação automatizada e aumenta a conveniência e a segurança do utilizador.

Sistema de arrefecimento: O arrefecimento por ar ou água é utilizado para evitar danos decorrentes de superaquecimento durante uma operação prolongada.

Segurança: vários elementos de segurança garantem a segurança do operador.

Fluxo de trabalho:

Preparação do material: Colocar o material a triturar na porta de alimentação, assegurando-se de que o tamanho do material seja adequado à máquina.

Iniciação da máquina: iniciar o motor, a máquina começa a funcionar e os eixos duplos começam a girar.

Processo de trituração: O material entra na câmara de trituração da trituradora de eixo duplo, onde as lâminas do eixo duplo rasgam e cortam o material, quebrando-o gradualmente em pedaços menores.

Descarga de material: o material triturado é descarregado através da porta de descarga, normalmente para processamento adicional em uma cinta transportadora ou outro equipamento.

Monitorização e regulação: o operador pode monitorizar o estado da máquina através do painel de controlo e efectuar os ajustamentos e manutenção necessários.

Limpeza e manutenção: Limpeza e manutenção regular da trituradora de eixo duplo para garantir uma operação estável a longo prazo.

Especificação do triturador de eixo duplo:

|

Tipo de modelo |

Dimensão ((mm) |

Tamanho do alimento ((mm) |

Lâmina ((mm) |

Potência do motor ((kw) |

Peso ((kg) |

|

TT-S600 |

2300x1500x1620 |

600X460 |

200 |

11 × 2 |

1580 |

|

TT-S800 |

2820×1600×2050 |

800X720 |

260 |

15x2 |

3500 |

|

TT-S1000 |

3300 × 1900 × 2200 |

1000 × 800 |

300 |

22x2 |

5000 |

|

TT-S1200 |

3500×2000×2500 |

1200×980 |

320 |

30×2 |

6200 |

|

TT-S1500 |

4100 × 2260 × 2800 |

1500 × 1000 |

550 |

55×2 |

7000 |

|

TT-S1600 |

5800 × 2400 × 3300 |

1800×1206 |

560 |

75×2 |

7500 |

|

TT-S1800 |

6100 × 2700 × 3500 |

2000×1490 |

600 |

90×2 |

8900 |

Oficina de máquinas de trituração:

![]()